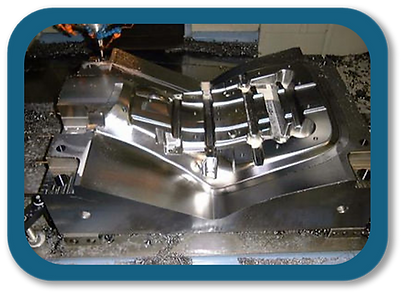

Injection Molds

Leading-Edge Technology

With our in house developers, we have developed software processes to significantly decrease the lead time of the mold building process. We can reduce a typical mold build time of 6-12 weeks to just a few days. With this advancement, our customers are able to get real plastic injection molded parts to use as production or prototypes.

Low Cost High Volume Engineered Molds

At Kettle Moraine Metal Products, we brought together technology with engineering. Because of this, the cost of a mold at Kettle Moraine Metal Products is often less than most injection molding companies charge for a prototype mold. Since our process and technology have reduced the build time up to 75%, this gives time for our design engineers to put real engineering into critical features of the mold in order to guarantee the mold for the life of the project. Most molds do not hold up long because they do not spend enough time at the engineering stage. As a result, our customers are saying that they often skip rapid prototyping or 3D Printing because our process is so fast and affordable. They are using our molds for Prototype, Bridge, and Production part runs.